- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

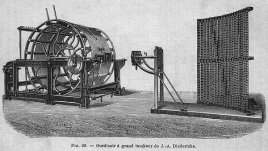

Mechanical Warping Machine:

The mechanical warping machines are constructed with very variable devices depending on the work that is required of them. The main aim of the manufacturers is to establish universal warping machines on which it is possible to fabricate all the materials and the different chain arrangements. These warping machines are equipped with a number of improved devices which can be rapidly used, adjusted or immobilized as the case may be, in order to obtain a better work in relation to the type of fabric to be treated and the maximum yield.

The different features and features found in the silk-woven fabrics of Lyon are:

Frame: The frame of the mechanical warpers is made of cast iron. It is generally composed of 2 feet or sides maintained by spacers, the dimensions are subordinate to that of the drum, and its forms to the constructors as well as the different organs with which they are provided.

Drum: The drum is placed horizontally, its circumference variable, it can be 2m50, 3m, 4m and even 5m, its length is also very variable and depends on the width of the strings to be woven. The drum is composed of a tree which carries 3 or 4 cast iron rings around which the wooden sleepers are fixed at regular intervals. At its two ends the drum generally carries a large cast iron circle, one of which is used for its warping and the other for braking for folding. At one point of the drum and between two crosspieces is an iron rod with hooks after which the betting starts, at one end of the drum (where the warping begins) is found in some cases on The bars of adjustable cones of very varied shape, the purpose of which is to raise the first setting to the inclination of the following when the material to be warped are large and form a great thickness on the drum.

Wire comb and wagon guide: The wires coming from the creel after passing through the feeder comb pass in a small variable reduction comb and the aim of which is to drive and place the wires exactly in the width they must have on the drum. These combs are of various constructions, the most commonly used are ordinary combs, 7 to 10 cm wide by 12 in height, also extensible combs and so-called fan combs are used to vary the wafer width for the same Number of yarns without having to be transplanted with a comb, that is to say allowing the very rapid and very exact width of the yarns forming the setting. The carriage carriage is merely composed of a casting plate which slides on a very straight part of the frame situated near the drum, it also carries in many cases a small deflection roller under which the wires pass, wrap on the drum. The movement of the carriage is automatic, it varies according to the material size and the length of the warps, its displacement can vary according to the cases from 5 to 25 mm per 100 m of wire wound on the drum.

Counter: All mechanical warping machines are equipped with a counter which automatically stops the warper when the warp reaches a certain length, counters are generally provided for 1000 m with automatic stop and optional every 5 m and ringing for The additional coatings.

Mechanical bending:

The bending is carried out on the warping machine, the warp being in width on the drum, the roller or beam is placed in two bushings situated on the opposite side to the warping. One of these two sleeves fitted with a swivel which penetrates into the roller is controlled in the gears to produce the drive of the roller. When the end of the chain is fastened to the roller, it is sufficient to put the folding clutch in motion to wind up the warp, taking care to place cartons at determined intervals as in the arm folding.

Some warping machines have a device that makes it possible to straighten the inclination of the bets given to the warping so that the warp turns wind up uniformly. In other warping machines, the chain passes over a guide roller which is moved by a reciprocating motion and which guides the chain with a displacement of 2 to 3 cm on the warp beam.

Mechanical warping

The types used in the mechanical warping are of very diverse shapes and arrangements, the number of spindles which they can receive varies with the type of material to be treated, it is generally according to the case of 400 or 800 spindles, sometimes even Of 1000 pins. The creels are usually mounted on a mobile carriage making it easy to move and focus.

A - Inclined cantre:

In inclined warps the pins are fixed and arranged in oblique parallel lines on wooden crossbars joined to a rectangular frame mounted on a cast iron trolley. This arrangement of the spindles is necessary for the regular unwinding of the wires which come behind the creel and pass after having passed through another comb on a glass bar or a roller which places the wires on a horizontal sheet which is easy to monitor and which can be remoulded.

This system is recommended for the warping of the pile warps of velvet fabrics, warps that it is necessary to remond before weaving to obtain a greater production.

Sloped chests are usually constructed for large pods or coils. The number of spindles is usually 400. They are also made with or without comb bracket. When the feeder comb is not carried by the creel it is mounted on the guide carriage placed in the warping machine.

The use of these creels is also dependent on the fact that, although they are fixed, they can be large and bare and have a wooden spindle or tube forming a pivot, the large spindles directly receive the pugs and give a high resistance to unwinding, are used for the warping of large materials such as schappe, mounted cotton or some large unbleached silk threads.

Spindles with pivot spindles, which greatly reduces the resistance of friction, are used with advantage for the warping of materials less resistant than schappe such as bristles.

B - Vertical creases:

Vertical churches are of very different shapes, the rack generally affects a parabolic shape or the shape of a V. The number of pins depends on the materials and articles, it is generally 400 for the wires on pugs and 800, or even Even 1000 for wires on reels. The pins for pats can be fixed with wooden spindle or without spindle or mobile, mobile pins are most often used for materials cooked or soft, they are supported on one side by a toad and on the other by a Steel hook. In the latter case, the friction is zero. The spindles of the 800 bobbin creels are generally fixed.

The rails are also mounted on a carriage with a reed comb, in those of 800 reels, and for some wires mounted very twisted, there is interposed between the creel and the reed comb a collet board, each wire passes through a porcelain eyelet, this device Avoids the sons who release and confuse in the others.

In the warping of greaves where intensive production is mostly sought, the use of 800-reels is generally used. The advantage is to allow the worker to warp 800 threads at a time.

When silk is more delicate or of greater value, the creature of 400 pothes is preferable, the worker being asked to do a more careful than fast work.

The spindle boards have the advantage of requiring less effort on the yarns to cause the penguins to unwind and thus allow, without risk of too many fractures, to warp a little faster provided that the nature and the strength of the silk does not oppose it.

In the case of small drum warping machines, it is preferable to use relatively low inclined cantres, while for warping machines the straight chains which are higher are used more often.

Comb:

In mechanical warping, the workpiece can not be moved with the fingers by selecting the threads one by one as in the warping, it is obtained with the aid of a special comb called for this purpose. .

This comb is of a particular construction and has 2 kinds of teeth: the odd teeth, for example, are free over their entire height while the even teeth are lined with welding at their upper and lower part in order to limit the displacement of the threads Who are placed there.

The number of teeth of the combs is necessarily equal to that of the pins of the creel, they are also constructed single chain with a free tooth a welded tooth, double chain with 2 free teeth 2 welded teeth, etc ...

All the threads coming from the creel usually pass underneath and above the glass canes, the aim of which is to bring them back to a horizontal plane, then they pass through the reed comb and head towards the small reed comb which leads them to the drum of the warping.

Practical hand weaving course

Lyon Municipal Weaving SchoolProfessor A.CREPT - Year 1912-1913

The handwritten course has been copied by us.This hand weaving course on looms was used until the 1980s.