- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

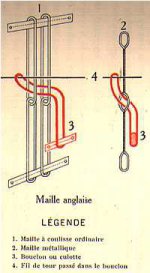

English gauze has two kinds of yarns, straight or fixed yarn and tower yarn or matching yarn. The 1st never raises, the other evolving once to the right of the fixed wire, once to the left. The tower wire is returned to the right of the right wire in an ordinary beam called the smooth link and to the left of the same fixed wire passing underneath in a special smooth beam called the English rail. It is by the alternate evolution of these two meshes placed to the right and to the left of the fixed wire that the English turn occurs. The photo of the sample is of course very much enlarged.

This english gauze was woven by us in our workshop in 1980. It is composed of a chain and a weft in fine silk schappe and was dyed in piece (ie after weaving). Was made of scarves of 1m60 in length.Unfortunately the english smoothes in cotton, already very old arrived at the end of race soon after. The thread was rocket, and they became unusable.

Example of English gauze

Cotton mesh and metal mesh

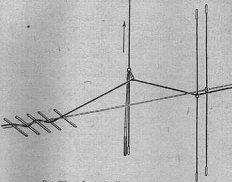

Lift of the turn wire by the connecting rail

By modifying the number and play of the straight wires and the wires of the tower, as the number of hits of the networks, it is possible to create many armatures of English gauze.

We have also made gauzes sans-vers, gauzes double-face, pekins, bayadères, fantasies and many others that we will not describe here.

5 - Warping of the Gaze chains

The straight yarns and the lap threads of conventional gauzes are frequently of the same size and are coiled together on the same roller. In this way, very perforated gauzes are obtained, the turning wires of which strongly enclose the straight wires and cause them to undulate, giving the formed groups a twisted appearance. The towers of the tower turn on another roll when their evolutions around the straight wires must be very apparent. In this case, the tower yarns are normally of a different quality or a much larger size than the straight yarns.

Lift of the turn wire by the English rail

This process is mainly applied in very perforated gauzes for which it is important that the parallelism of the groups of yarns is perfect.

Figure 1

In FIG. 1, this remounting combination is represented by only two wires, one straight wire (in clear) and one turn wire (dark). Back, the right yarn is put back in a stitch of the right body. Immediately forward, the turn wire is put back into a mesh of the matching body, to the right of the right wire. The turn wire is resurfaced but 17 cm forward, in a loop knit slipped into the eye of the ordinary stitch of the English saddle, left to the left of the right yarn.

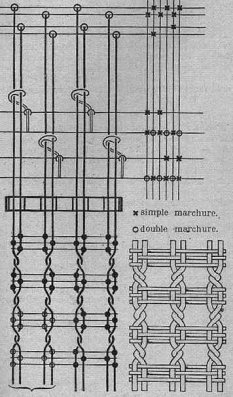

3 - Mass gases - Gazes à regard

In conventional gauzes, all the tower wires can be fastened together, on the same side of the right wires, on the right in a network and on the left in the next network. They can also be opposed in each network, ie to be fixed to the right in a tooth (or group of teeth) and left in the neighboring tooth (or group of teeth). In the first case, the gauze is called mass; In the second case it is called gaze.

The gazes are more frequently employed than the gauzes, because they communicate to the tissue a generally more regular appearance, at least in fine gauzes; The mass gauze often giving these fabrics a barred appearance comparable to that of the cane.

The gaze gauzes are obtained:

By reverse resetting, the straight wires preceding the tower wires in a tooth, or a group of teeth; The tower yarns preceeding the straight yarns in the tooth or the next group. The number of healds of each body is thus reduced to a minimum.By causing the straight threads and the tower threads to follow in the same order in all the teeth (remounting followed) and forming the gazes to gaze by the play of the healds. The number of heddles of each body is then doubled compared with that required by the returning rebar.

4 - Observations on thread play

It should first of all be noted that the straight wires can be kept constantly under the weft, remain constantly in the bottom, while the tower wires can rise on all the blows but passing under the straight wires in their movement d One side to the other of these wires.

The combined play of the straight wires and the tower wires, especially the turning of the wires to the right and to the left of the right wires, causes the tightening of the weft strokes in the networks as it causes the tightening of the wires grouped in the teeth. In order for intervals between networks to be as strong as those between the teeth, the tower wires must be raised on the first and last stroke of each network. When this rule is not observed, the perforated effect is partly destroyed by the displacement of the fragments which detach themselves from the networks and obstruct the interval which should exist between them.

In order to increase to a certain extent the interval between the groups of threads (the teeth of the gauze) and, above all, to regulate these intervals, comb stitching is frequently carried out on combs with a finer reduction than Would impose the groups of wires. At the comb stitching, an empty tooth (sometimes two) is left between each group of threads, passed in full tooth.

The real English gauze

1 - Description

Under the name of gauze, it is common to denote openwork and transparent fabrics obtained by manufacturing processes which differ essentially from those used for other fabrics. The term gauze, however, is used to designate taffeta, the transparency of which is simply due to the spacing of the warp and weft yarns; They have no particularity of manufacture and the name of gauze is then only a misleading commercial name.

The true gauzes, or English gauzes, are necessarily composed of two kinds of threads, to which the names of straight wires (or fixed wires) and of tower wires have been attributed. The straight wires remain unbonded or bonded by ordinary means simply passing above and below the weft, while the tower wires, in addition to the crossing that they may have with the weft, Bypass the straight wires. In conventional gauzes, this movement is limited to the only change in the tower yarns on one side and the other on a yarn or group of straight yarns. After passing below these threads, they are bound by a weft to their right and then to their left. But the movement of the tower wires can be amplified and provide complex gauzes. They can, for example, evolve around several groups of straight wires, wrap the straight wires of a whole turn - even of several turns - form by their sinuosities small patterns of drawing, superimpose themselves to other threads of turn. The English gauze thus comprises numerous types of armor, of very different characteristics, due to the multiple combinations to which the turning wires lend themselves. It should be noted that these forms of crossing do not necessarily lead to perforated fabrics; They are also suitable for the formation of tight and thick fabrics.

The gauze armor is defined by the number of straight wires and turning wires that cross together and by the number of strokes during which the tower wires are fixed to the weft between each movement around the straight wires. Thus, a so-called 4-wire and 2-wire gauze indicates that 4 wires evolve together and that the turn wires included in these 4 wires are connected for 2 consecutive shots, to the right and then to the left of the straight wires. In the conventional gauzes, these 4 wires make up a tooth because they are stitched in the same tooth of the comb (the tower yarns could not of themselves bind the two sides of the straight yarns if they were separated by a tooth Comb blade). The frames grouped by the play of the turn wires constitute a network or a rib.

The ratio of the gauze armor consists of one or more groups of wires, ie one or more teeth, and an even number of wires. The number of wires in this ratio is subordinate to the numbers of the straight wires and the tower wires crossing together and the number of teeth making up the ratio. The number of hits depends on the importance given to the networks and the number of networks.

2 - Reassembly of conventional gauzes

The English gauzes are obtained by different means. Among the remelting processes enabling the execution of these fabrics, we shall retain the one according to which the play of the threads is obtained only by raising them (smooths working at the rope) and which is applied to the manufacture of conventional gauzes of All kinds, simple or armored. This method requires 3 shed bodies, one for the straight wires, the other 2 for the wires.

The straight threads are put back into a first shed body, the right body, consisting of one or more healds.

The tower wires are passed through a second body, the matching body consisting of one or more healds immediately in front of the right body. They are then put back in a special body, the English body generally comprising only one or two English hems. This body is placed about 17 cm in front of the body of correspondence.

The healds of the right body and the body of correspondence consist of ordinary mesh, slide or metal mesh, while each English hem consists of both ordinary meshes and loops fixed in the ordinary meshes or slipped into the eye of these sts. The whole of the loops belonging to an English smooth bears the name of panties or bouclon; They are fastened side by side to a leg, at their lower part.

The tower wires which are intended to circumvent one or more straight wires are on one side of these wires, individually placed in the meshes of the healds of the correspondence body. In order to reduce the number of the English healds, they are then put back together in the same mesh of the bouclon, this mesh being supported by an ordinary mesh of the English heddle left on the other side of the right wire. It is thanks to this double control that the tower wires can be raised and fixed on one side and the other on the right wires; On the one hand by the lifting of the healds of the body of correspondence; On the other by the raising of the English body.