- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

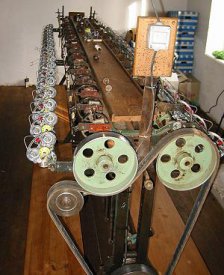

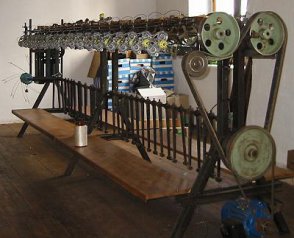

In spite of its massive air, this machine does not require the use of a large motor, with few moving parts: two longitudinal shafts over the entire length of the machine are rotating through the two large green pulleys located just Above the engine (220V-2CV). Each of these 2 axles supports 17 wheels that will drive the spools on friction roller spindles.

One of the 17 bobbins on the right friction driven by a wheel of the right-hand shaft.

On the left-hand shaft there are 17 wheels that drive the coils.

We have added between the fleets or cones located almost at ground level and the wire guides of porcelain of the systems of braking of the wire making it possible to control the tension to be given to the wire which winds on the coil.

Adjustments allow the reciprocating stroke to be adjusted to match the width of the bobbins or pugs.

Moreover, the rotation speed of the motor must be adapted (pulley with groove) so that the speed of rotation of the coils is not too fast, for example 900 turns.

This relatively old machine is rather rudimentary since it does not have an automatic shut-off system when a coil is filled or a wire breaks. So you have to watch it like oil on the fire ...

From each side of the bank to be unwound, two round iron rods of the length of the bank have a horizontal reciprocating motion from right to left and from left to right. They support the thread guides (here a yellow and a pink) of porcelain in the center of which the thread of the fleet or of the cone makes its passage to go on the reel or the pug. This reciprocating movement allows a cross-winding on the reel.

The banks to be reused used in the weaving workshops were of the same nature as those of the millers. This bank to reel that we have restored has 2 times 17 spindles allowing to reel 34 fleets or cones at the same time. It is modular and could be 2 or 3 times longer. It is used to transfer fleece or cone wires to cheek bobbins or pugs that will be used for warping and canning.

The mills used two kinds of machines, the banks to reel (or winders) and the mills. Banks to unwind were used to transfer raw silk received in fleets (silk skeins) on reels. The mills were used to assemble and twist greige bristles after being transferred to reels and thus create the weaving yarns delivered to weavers for immediate weaving (dyeing) or weaving after decoupling and dyeing (wire dyeing).

Unwinding

The bank to unwind presented comes from an old mill of the Haute-Loire (43). The milling was a factory carrying out the work, that is to say the transformation of raw silk thread from spinning by assembly and various twists in order to create the various silk threads intended to be woven. The mills were generally situated at the bottom of the valleys, at the edge of the rivers which supplied the machines with motive power.