- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

The guides or barbels are generally controlled by two cams driven by a series of gears, all referred to as the adjustment.

The adjustments of the mechanics to be unwound are nearly all constructed according to the same principle, and can be adjusted according to the working of the wire to be unwound, and formed it to give to the puges or coils.

For pugs the back and forth movement is broken, for the reels it is uniform.

The adjustment is said to be small-crossed when the turns of wire are wound substantially parallel to each other and at large cross-section when the displacement of the wire is very large and fast, about 1 cm per turn of wire in some machines.

The unwinding of cottons and wools for chains is generally carried out on special machines called a winding machine, on which the wire is wound in the form of a very large bunch according to a large-scale adjustment.

Detranning:

The silk yarn wound directly on the pug has certain unwinding defects, such as false turns, bad knots, etc., which can cause waste of time and waste in the following operations.

To avoid this it is necessary to subject the wires to a rewinding called de-hoisting, the sole purpose of which is to purge the wire from the unwinding defects.

This detranning operation is generally carried out on the machine to be unwound. The warp removal must be done on uniform pats as weights and dimensions. The regularity of weight facilitates the verification of the weight remaining on the pugs, uniformity of dimension is necessary to obtain a good warping.

In the ordinary float where the layers of yarns are arranged substantially parallel to one another and the jumpers formed of a number of small fleets varying in length from 1200 to 2000 meters, this preparation takes the name of use and consists of To separate the small fleets and to parallelize as much as possible the turns of wire. For this purpose the fleets are placed on a large anchor fixed horizontally and designated under the name of traffuser, then they are skillfully shaken and turned with the hands.

In the fleets wrapped with the Grant setting, the operation of the traffic operation itself is suppressed, the ghosts being ordinarily formed from a single piece varying from 12000 to 20000 meters, these fleets are simply extended so as to place the layers of wire Which is obtained by extending the capillaries well horizontally.

Pug shapes and yarn winding:

The pins or coils used for unwinding the silk thread are cylindrical in shape and generally terminate at their ends by a rim of varying height, in some cases, however, simple pipes made of bpois or iron or even of cardboard are used.

For unwinding, the pugs are placed on pins forming an axis, one of the ends of which rests on a pulley which is driven by a rotary movement driving the pins and the pugs.

The thread coming from the fleet is guided on the pug by a guide called a barbin, which is reciprocated in a reciprocating movement to arrange the turns of thread according to a crossing designed to give shape and hardness to the pug Which renders the transport and handling thereof free from the risk of landslides.

Preparing chains and frames

All the textiles undergo before the operation of the weaving various preparatory manipulations which have the aim of appropriating the threads to the role that they are called to play during the weaving.

Wire unwinding and unthreading:

Unwinding is the process of winding the delivered yarn in floats on coils known as pugs, coils, coils, etc.

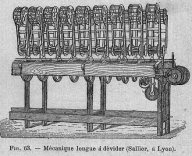

This operation is carried out on machines called mechanical to be unwound or bank of unwinding.

The fleets to be unwound are placed on devices whose shape and name differ according to the nature of the yarn and the formation of the fleets.

For silk, two kinds of floats are used. The first and oldest is called ordinary adjustment and is used less and less, the second is the floating crossed float according to the Grant setting. The vessels which are employed for the reeling of the ordinary fleets are disregarded under the name of guilds, those employed for the reeling of the fleets which are carried on under the name of tavelles.

Trafusing or preparation of fleets:

The very operation of the reeling is always preceded by a preparation of the fleets which is necessary to place them on the guineers or tails under conditions favorable to the unwinding of the yarn so that this unrolling takes place as quickly as possible and as regularly as possible.

Practical hand weaving course

Lyon Municipal Weaving SchoolProfessor A.CREPT - Year 1912-1913

The handwritten course has been copied by us.This hand weaving course on looms was used until the 1980s.