- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

Perforated fabrics

Lecture given on 15 December 1943 at the Ecole Supérieure de Tissage in Lyon

By L.Tissot, (Full text)

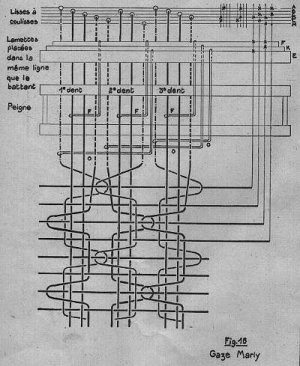

The Marly gauze is characterized by hexagonal days obtained by making the tooth threads of two adjacent teeth crochet together.

It is for this reason that, as in the pearl gauze, there must be beams in front of the comb to control the displacements on 2 teeth of the tower wires.

Dufour gives the following description of the remaking:

Reassembly of 1 tooth behind the comb:

1 thread of turn on 1 smooth A1 thread of turn on 1 smooth B1 thread of turn on 1 smooth C1 thread of turn on 1 smooth D

For a second tooth, same order of restoration, only the first thread of turn is passed over a beam L and the second wire on a beam M.

Remounting in front of the comb

The turn wire of the heald A is passed through a half mesh which passes under the 3 wiresFollowing the same tooth, top 3 threads and underneath 1 thread the next tooth.

This half mesh corresponds to the lamette E.

Remounting in front of the comb (continued)

The right thread of line B is passed through a half mesh which passes over the next straight threadAnd below the turn wire, this half-mesh corresponds to the lamella F.

For a second tooth in the same arrangement, only the half-mesh O corresponds to the lamette K and the thread which it takes is passed over the slide rail L.

The arrangement of the healds and the above remounting requires the use of appliances capable of giving the half-meshes the development which they must have in order to transport the wires from the point where they are placed in the primitive remaking and to allow the On which the latter pass freely. For example, as the heddle C changes, the wire under the half-mesh F, it must be folded back in double movement so that the thread it contains remains at rest. It is naturally the same with the half-mesh O, whose development must be twice as great; In a word, the movements must be combined with the approximation in which are the points of evolution which, if placed before the comb, do not prescribe a more considerable development, while preserving the relation of the different evolutions.

I have finished, gentlemen, not that I have pretended to have exhausted a particularly rich subject, upon which the personal labors of each one may still permit innumerable little discoveries.

Gazes, in general, are an exciting subject of study which we have perhaps abandoned too little in Lyon in recent years. To restrain myself in this technique, I have the impression that it is a little back to those old traditions of Lyons, which once made the strength and grandeur of our factory.

L. Tissot, December 15, 1943

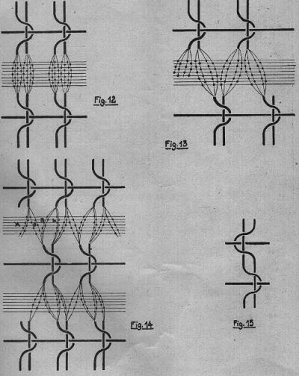

If, in order to obtain a very important openwork, two consecutive shots of crocheted gauze, it would be necessary, in order that the second should not go beyond the work of the 1st, or else make these 2 shots in contradiction , As shown in fig. 14 (assuming the ground shots have been deleted), or have the reverse play on the second shot of the first shot, as shown in fig.15, but this would cause the door to be turned Needles on the second shot. It may happen that it is desired to group in the network formed by the two groups of wires which hook a certain number of hits, for example. In this case (as in the case of a beijing, for example), after having made the choice of the groups of threads on the first stroke, and taking the ones that must rise above the weft in the hooks of the needle holder, Hangs the needle holder at its high position and passes the 16 consecutive strokes without unhooking the apparatus, treading at each stroke the step of the mechanism to change the pitch of the bottom parts.

The stroke on which the needle holder is made need to be made of resistant material, often the ground grid is not strong enough and it must be replaced either by the same material at several ends or by a larger material and More resistant. By means of all these combinations, we can produce very different effects, which can be varied still by modifying the number of taffeta blows placed between two strokes of needle-carriers: when there are only four or 5 taffeta shots loosely set between 2 shots of needle holders, the threads do not have time to get back in width and we get a design quite different from that we have with about thirty taffeta coupes reduced Between 2 strokes of needle holders. It is also possible to have, in addition, a shed body carrying threads which will not be gripped either by the back of the hooks or by the hooks of the needle holder and which always remain at the bottom of the needle carrier. In the taffeta or shaped bands, these threads will play the same game as the others.

Formerly, it has made articles to the needle holder with organsin chain cooked, color or black. That is, you can use even delicate materials in a chain. However, it is recommended to use resistant materials.

There does not seem to be a system nowhere to mechanically make this crocheted gauze which is so commonly performed by hand. The system constructed by Staubli and described at length by Lamoitier in his Study of Gauze, seems to have had no follow-up. Lamoitier himself says that Staübli has abandoned the construction of his apparatus. The crocheted gauze therefore remains a fabric that can be produced only in the hand loom, but of a weaving current in Picardy and Cambrésis where several hundred workers could be found to work this article.

Gaze Marly

I dwelt a little on the crocheted gauze, because it seemed to me that this was an interesting process, little known in our region and widely usable practically. I shall be much more brief in the description of the gauze Marly, for already in 1899 Leclerc, in his ABC of the weaver, indicates it as one of the most difficult to obtain, and even Dufour, in his Treatise, in 1855, Mentioned as exceptional. At present, the process is generally regarded as impracticable, claiming that even in the hand-craft it is necessary that the worker constantly help the children to make their movements with the fingers. The description which follows is therefore of purely theoretical and documentary interest; I thought, however, that one could not pass over in silence a process as curious as this one and as old, for I confess that it has always been for me a great subject of astonishment that to see the gauze Marly described thoroughly By Paulet in his Encyclopaedia, just as the taffeta movement.

Let's start working and weaving a taffeta band first. When we arrive at the stroke on which the needle-holder is to operate, we press a step on which are suspended the two heddles C. No. 1. This has the effect of raising all the odd groups of 16 wires which we shall call for the ease of description, groups A (fig. At this moment, the worker has attached to the leaf his needle holder (which often remains on the face as it weaves the taffeta parts) and, to the left of each group of threads A, plunges a hook The hooked part of the hook being turned outwards with respect to the groups A. The worker, by lateral displacement given to the apparatus from left to right, pushes the hooks The groups of wires A until they are brought to the right of the groups B (even groups of 16 wires) which, in the rest position, are to the right of the groups A.

When groups A have been crossed thus on groups B and brought to the right of these groups B, the worker grasps all groups of threads B with the hooks of the needle holder, raises them and hooks his needle holder on the Beating by the second rod which makes it possible to hang it higher. It is now a question of passing the frame to preserve this crossing. The workman, abandoning his march, crowds another who commands the mechanics, and causes all the healds of bodies No. 1 and No. 2 to be folded down. The groups of threads A descend on the leaf of the leaf, while the groups of yarns B remain suspended in the hooks of the needle holder. The step is formed. All you have to do is go through the shuttle and let the groups back up. Then the worker unhooks the needle holder and comes to pack the blow with this apparatus. The leaf should not be used for this purpose, because the threads would be cut in the intersection of the groups of threads in front of the comb.

The groups of wires A and B need to be wound separately because at the moment when all these wires are folded down by the mechanism, the wires of groups B which are retained in the hooks of the needle holder must be released in order to be able to Follow the impulse given by the healds without breaking. The roller carrying these groups of wires B is in connection with the mechanism, which discharges the roller from its counterweights by lifting them at that moment.

Of course the reduction introduced into the taffeta parts can not enter the crocheted parts, and the worker advances the regulator a little.

In practice, the craft has three steps, since it is necessary to foresee the case where a group of 16 wires, after having been crocheted to the left with a first group, goes crochet right with another group of 16 wires, as indicated in FIG. 13. The third step, of which we had not spoken, controls the healds of the body 2 and makes it possible to raise the groups of threads B. In the case of FIG. 13, it is sometimes a roller and sometimes l The other which will be released by mechanics.

There may be a more complicated case, that is the one indicated in Figure 14, where, according to the expression of the region, the bracket is "said and contradicted", that is to say, counterstepped. The warping must be done in 4 rolls, one for the groups of yarns, one for the groups B, one for the groups bb, one for the groups AA, one for the groups AA.

The remounting will be done in 4 bodies:

A first group of healds for the wires AA second group of healds for theA third group of healds for the threads BA 4th group of healds for the threads b

And there will be in the loom 5 steps of which one for the control of the mechanics and 4 others to control each of the 4 groups of healds A, a, B, b. With each picking there will be 2 rolls that the mechanics will release by lifting their weights.

We have hitherto spoken only armed gauzes; It goes without saying that if an organized gauze organization is available, it is possible to multiply, at infinity, according to the most varied designs, the oppositions of open-work effects and solid effects.

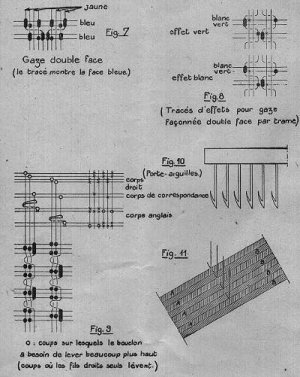

Double-sided gauze

We would like to mention in passing, among the fancy gauzes, double-faced gauzes. FIG. 7 shows the plot of armouring of a gauze warped by 1 blue thread - 1 yellow and halftone - 1 blue line; The trace shows the blue face. In detailing the armor, it will be noted that the set of straight blue wires is combined so that these wires are almost completely on the blue face and completely conceal the yellow right wire which passes upside down on the yellow face. As for the yellow turn, it appears on the blue face only by imperceptible dots (raised on the weft bends) which conceal the blue straight wires.

A similar double-sided gauze combination may be made per gauze; FIG. 8 opposite applies to a gauze white warp 1 green strike - 1 white strike and represents the green face. The white face could easily be seen, as shown on plot 8. Consequently, it would be possible to make a double-sided gauze by alternating in a drawing the two green and white effects.

Gaze double tour

A particular mention seems to us to be made to double-turn gauzes, in which the turn wire makes a complete turn around the straight wires, thus remaining constantly on the same side of the straight wires, whether it works by the correspondence body or by the Body. This complete turn made by the turn wire around the straight yarns ensures greater strength to the fabric and at the same time allows a greater opening without inconvenience. Real, solid and very perforated netting is thus realized. The attached drawing 9 shows the necessary organization and gives an example of armor for this kind of gauze.

A triple gauze gauze would be made in the same manner, by modifying the pantaloat accordingly.

Cardboard gauze

It is, moreover, possible to go farther still, and to make a much greater number of turns turn around the right wire; We can envisage 6, 8, 12 turns if desired, thanks to a quite particular device that you will be able to see still in place here at the School, and which essentially comprises a ratchet, including a number of teeth at least equal To the number of turns which it is proposed to give in turn around the right yarn. On either side of the center are pierced, in this ratchet two holes, in each of which is passed one of the threads which it is proposed to make work together. The rotation of the ratchet of the value of a tooth causes the two wires to turn one around the other; It will be enough to turn the ratchet of six teeth so that the two threads make six turns for example, one around the other, before one raises one of them to pass the weft and fix thus The twist. It should be noted that this twisting of the wires takes place not only forward but also behind the ratchet and that in order to continue weaving it is necessary after a few revolutions to reverse the direction of rotation of the ratchet in order to destroy The twist that occurred back. This inversion of the movement has no influence on the torsion produced before, since this twist has been fixed by the weft. This process is similar to cardboard weaving, known since the earliest antiquity, applied in ancient Egypt and studied only thoroughly in recent years.

Gaze of Picardy

We may reproach all the combinations of the gauge apertures of which we have just spoken, that they do not allow very large openings to be made, genuine holes in the fabric, as are found in certain lace. This comes from the very principle of the gauze, which allows the displacement of the towers only around the straight threads stuck in the same tooth. Theoretically, the perforation is thus limited to a comb tooth and if, in practice, it seems sometimes more important, it is thanks to artifices of grouping of threads or blows or judicious dispositions of empty teeth. In order to make very large openings, it is necessary to be able to move a tower wire of more than one tooth around the straight wires and this leads us to talk about old processes, which unfortunately disappeared completely from the Lyons region but are still In use in Picardy, especially in the Bohain region and in the Cambrésis, all of which allow for very large displacements of the tower yarns; We are talking about the crocheted gauze made at the needle holder and the gauze Marly.

Crocheted gauze

In the crocheted gauze, it is possible to crochet together a number of threads such that the interval between two crocheting points, that is to say the diameter of the day, is commonly 1 cm or even more. The various samples that you have there in front of you will allow you to realize it.

If it were desired to use ordinary gauze assemblies to make these days, it would be necessary for the two groups of 16 threads, for example, which need to hook together, are both in the same tooth of the comb, that the first group is put back on A straight body and a body of correspondence, while the 16 threads of the second group would have passed together in the same stitch of a buckle commanded by the English body. Inevitably, the 32 threads, for example, passed in the same tooth would be grouped together and it would hardly be possible (except in a very coarse fabric made with very large materials and where the scratches would not count) to design a band of taffeta coming Of one of these effects of crocheted gauze formed on a blow. For in this taffetas the 32 sons would not be able, despite the armor, to be put back in width.

This is why the hooking of the groups of wires is obtained by a very different process and by means of a special apparatus to the region called the needle holder.

Description

It includes a sort of strong flat wooden ruler with 3 cm long metal hooks (this rule itself is made up of two wooden blades screwed onto one another and often even glued).

The size and shape of these hooks, their spacing, is variable according to what one wants to do. Thus, for wool and large materials, the curved part of the hook is flat and therefore has some rather sharp angles, whereas these angles are rounded when delicate or delicate materials such as silk . It is also necessary that, depending on the size of the material, the hooks be open enough to contain all the wires. The difference between the various brackets depends on the size of the days to be obtained; The hooks are placed in the ruler of the needle holder at the desired interval for the points of the hooking in the fabric. The weavers make the needle-carriers according to the articles, as and when they are needed. But it is not necessary, in order to be able to work fluently, that one has more than 4 hooks to the centimeter. The object which is proposed being, moreover, to have great days, it would be contrary to this end, by seeking to multiply the number of hooks in the needle-holder.

At the ends of the needle holder are fixed two metal rods, one at the top of the ruler, which allows the needle holder to be placed against the sash when used, the other a little lower which Allows the machine to be lifted at a height of 3.5 or 4 cm higher than the rest position.

The hooking obtained by the needle holder taking place in front of the comb, the comb stitching is of no importance, just as the comb count can be as tight or as loose as desired.

Of course, the fabrics for which this apparatus is used are not only crocheted, as the manufacture would be extremely slow and the fabric obtained too current. They are made of small taffeta bands or shaped taffeta background that can be made as tall or as thin as you want, strips that are separated by hits on which the hook is made, which always causes Days at this location.

Operation

Suppose we have to make a fabric with a succession of taffeta parts and crocheted parts. What is important to decide in the first place to make the fitting of the craft is the number of threads that one wants to crochet with one another. Let us suppose, then, that given the size of the day we want to have, on the one hand, and knowing the number of threads per cm in the fabric we want to obtain, we decided that two Groups of 16 wires. We will do a packet resetting by:

16 threads on 2 body slides N ° 116 threads on 2 body bars N ° 2

Depending on the number of yarns per cm, we will be required to put 4, 6 or 8 hems instead of 2 per body. Some of them have a somewhat different organization: instead of packing, they do a remounting followed by the addition of 2 or 3 other healds with very large stitches in which the yarns are given at the rate of 16 per mes example. These large-mesh healds serve only to separate the wires in groups when working with the needle holder. The other rails are used to make the taffeta.

But organizing with packet remittance seems more common and simpler.

The healds are fitted in the middle of the comb 3.5 cm from the flap of the door leaf, as they are intended to be used for lifting and lowering except when they are controlled by special steps intended to enable the groups of threads to be separated Needle holders, in which case they work at the lift, but only form a half-margin of 3.5 cm.

In connection with the production of apertured effects, it will be noted that, in addition to the grouping of the strokes in the same gauze step, the passage of the turn wire from right to left or from left to right at the moment of its command by the English body, Or by the matching body, makes it possible to produce a perforation in the fabric. If all the straight and revolving threads were constantly armed in taffeta, one would still have a small opening at the moment when the turning wire changes side with respect to the right wire, because at this point the weft encounters resistance to be compacted by the fact Of the crossing that has just occurred.

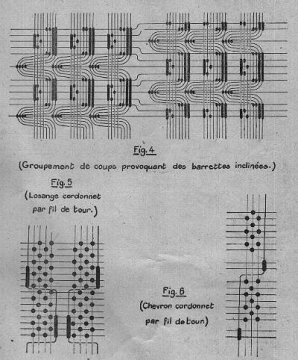

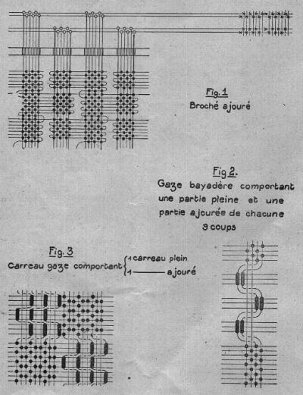

Perforations can be obtained from the same principles, either in pekin, or in tiles or rectangles. FIG. 3 illustrates this method of perforation.

Still on the basis of this principle that the blows are grouped together when they are in the same pitch, it will be possible to produce weft bars which are inclined between two solid effects as shown in FIG. 4, when in two adjacent teeth the grouping One or more strokes, sometimes with the previous scraps, sometimes with the following strokes.

The same principles of perforation would make it possible just as well to make fashion, instead of making simple bayadères, pekins or tiles.

Let us now consider the second case to which we have alluded above, that is to say, in which one has threads of turn in large matter and straight threads barely visible, so that the only movement which influences the " Appearance of the fabric is that of the tower yarns. The problem is then to produce real drawings with these only son of a tower and it is wonderful to see the feats of strength that one realizes with such limited means. Obviously, when one studies these effects, one finds that they almost always return to diamonds, chevrons or straight parts, and that it is by judiciously alternating these effects, or by Making more or less long, that one can realize the infinite diversity that one notes. Generally speaking, since it is a matter of showing these towers as much as possible in the area, efforts will be made to tie them together so as not to bury them and to make them pass as little as possible, towards. If there are straight parts to produce, no difficulty: we will be content to always arm by the same body as long as the right part.

As far as the production of diamonds is concerned, it obviously requires the use of gaze in neighboring teeth, but also, above all, the possibility for the turning thread to place itself on a certain number of shots squarely straddling The straight wires, positively skewed. This result can only be achieved if the turn wire is not fixed on a certain number of shots. It is known that for a rising organization, the turn wire must rise when it is first ordered by a body, in order to fix the turn wire on the side where it raises this body; In the same way, when a tower wire is last ordered by a body, it will be raised again to fix it at the last stroke, before it is commanded on the other side of the right wire by l The other body. If this precaution is not taken, that is to say if, after having raised a turn wire by the correspondence body, this wire of turn is left in the bottom on 6 shots, for example before being controlled by the Body, this turn wire will be placed at an angle on the straight wires for the 6 shots. In the same way, if, after having commanded 2 turns, for example, this turn wire by the English body, it is left on a 6-stroke basis before being again controlled by the correspondence body, the turning wire will be placed Bias on the 6 shots, in the opposite direction to the position he occupied earlier.

Lane 5 illustrates the production of these diamond effects. Plot 6 shows that a chevron can be obtained by the same method.

To illustrate the way in which these sons of a tower straddle the straight threads, I chose the example of an organization to raise it, in order to be as clear as possible, since in our (Except for gauze looms), but I must point out to you that often, when the tower wire is the main effect and must therefore remain the More often on the side of the place of the fabric, the loom is organized in a flap so that this thread of turn can be closely monitored on the facade. I would add that the thread of the embroidery thread obviously needs to be hemmed on a different roll from the straight threads, which roller will be held loosely enough to allow the tow threads to make the twisty path that one Seeks to produce.

The subject of this talk is certainly not very current, for who is concerned about making days in a cloth at a time when everyone has great difficulty in obtaining a garment that preserves it from the cold? Do not see, then, in the exposition which follows, a purely theoretical study of the possibilities of the loom in the realization of openings.

We mean "the possibilities of the loom," meaning to eliminate voluntarily from our study all the effects obtained by perforating the fabric, by embroidery or by other manipulations of the same kind made after weaving, just as we will leave aside All openings produced either on tulle looms, on chain looms or on coil looms which, moreover, belong more to the family of the veil, knit or lace than to that of fabric properly so called.

Even so limited, the subject is still too vast to be treated before you in a session and especially I would like to avoid talking about things too well known by all so as not to tire your attention. That is why we shall not discuss light fabrics such as veils, muslins or georgettes, nor fantasies produced on these light backgrounds by oppositions of opaque parts and transparent parts such as muslin, georgettes devoured , And we will content ourselves with studying the real openworks obtained on silk professions.

Blank tooth pasting and weft passing

Let's start with the simplest effects:

Leave empty teeth in the fabric and we have an openwork. Not necessarily however, because if the frame is large enough, or the reduction sufficiently strong, one can have an opaque effect, despite the absence of a chain. This combination has often been used, either by economics, or to emphasize the weft, with the exclusion of any search for openwork.

But if, besides the presence of empty teeth in the vertical direction, we have, in the horizontal direction, passages without weft, we shall inevitably have at the intersection of the scratches without chain with bars without weft, genuine holes, Importance will depend on the width of these scratches. The process can not be used with any textile or with any armor if it is desired to preserve to the fabric its qualities of resistance indispensable for practical use, but in wool and in a more With a thread which has a hook, which is not smooth and does not tend to slip, this method has given rise to interesting results. The specimen you have before you is a palpable proof of that.

The same result can also be obtained by inserting in the warp and weft direction a material different from that of the bottom of the fabric, such as cotton which is chemically etched or rayon with acetate and which can be destroyed after weaving by manipulation (Heating the fabric to dust the chemically cotton or dissolving the acetate with acetone).

Posters

Always starting from empty teeth, here is an original method of perforation which uses the paperback to the barrel. The arrangement of the solid parts and the empty teeth must obviously agree with a division of embroiderer (80 tons in 120 cm, or 60 tons in 120 cm for example), since the openwork occurs where there is diving. Suppose, in fact, that you regularly have four full teeth, four empty teeth, for example, and two solid parts separated by an empty part, that is twelve teeth in all, representing a little less than the distance between the points of two embroidery cradles, Is a little less than 1.5 cm or 2 cm. It can be seen very clearly, as shown in the accompanying drawing 1, that a very marked void can be produced where the embroiderer plunges, since the frames deposited by the espolins will limit their travel on either side to the parts comprising chain. Obviously, if the fabric does not have any other weft than the stitched weft, it is essential that the perforation effect be produced in counterstep, in order to enable the embroiderer to connect the various solid parts together. But this obligation is not to harm, on the contrary, the appearance of the fabric. One could, moreover, free themselves by inserting a background pattern throughout the length of the fabric from time to time.

This combination of perforation lends itself to all sorts of fantasy, because on the edge of the solid stripes one can put thick yarns or yarns of bright colors that emphasize the solid effects, these yarns finding their replica in weft, so as to Crimp the entire tiles to the openwork tiles. Alternatively, by suitable filling of the embroiderer in several colors and by using the displacements which this apparatus permits, it is possible to make real openwork patterns, such as regular or irregular chevrons, serrated pecks, etc.

False gauges

We will mention only for the record, if you will, the effects of perforation obtained by grouping of threads and known under the name of false gauze.

Their interest is very great in practice, since they make it possible to obtain, at little expense, similar open-work effects of appearance to certain gauze fabrics. But precisely, because of this, they are too well known to all of you to make it useful to insist on it.Google Traduction pour les entreprises :Google Kit du traducteurGadget Traduction

Gaze lyonnaise - Gaze English

I am anxious to arrive at the real gauze, because it is the typical process of the openwork on silk looms. Not that all gauzes are necessarily fabrics to day; There are some which, in furniture, for example, are fabrics as thick and opaque as any fabric of hangings or sieges. But, conversely, is it not immediately to the gauze that one thinks, when it is a question of producing a fabric up to date.

Far be it from me to inflict on you a lesson on the gauze; Despite the pleasure I would have had to go back 15 years back to the time when I was professing at the Ecole Municipale de Tissage, place Belfort, I thought you would not mind taking me this way for beginners .

I shall not, therefore, describe the organization of a craft of gauze, as well as I am, nor speak of the ingenious devices for mechanically producing industrial quantities of simple gauzes like the marquisette. I shall pass over in silence the respective advantages of the masses and the gazes, in order to treat only a small part of the question, that which relates more especially to my subject: the production of perforations. How can one produce more or less perforation in a gauze? How can you create interesting drawings?

I - How to produce more or less perforation?

The more or less important opening of a gauze is a function of the confusion of warp and weft, the size of the materials, the armor. It goes without saying that, since one desires an up-to-date fabric, one begins by choosing a chain count and materials, which leave room for voids in the fabric. As for the reduction, there is no risk in wearing gauze to put too much, because it generally has difficulty to enter, the crossing of the gauze yarns opposing the entry of a large reduction . The influence of the armor on the perforation is felt as soon as one uses gauzes other than the gauzes 2 wires and 1 stroke, in particular as soon as one has several strokes per network. It is then, indeed, that one begins to experience difficulties in simultaneously realizing these two conditions which seem to be opposed: to preserve to the fabric the perforation which gives it its character whilst maintaining a sufficient resistance to slipping for That practical employment does not suffer. If we merely make mass effects by the towers, leaving the straight threads at the bottom, it is to be feared that the fabric will slip, but we have the maximum aperture of the fact that the blows Are grouped, like the threads, being in the same step. If, on the contrary, we weave abundantly in taffeta, straight threads and towers, we protect ourselves against slippage, but greatly diminishes the opening, and sometimes we even make it disappear completely. There is therefore a balance to be maintained, a balance to be achieved, in which the nature of the materials intervenes in turn to prevent sliding for example.

II - Produce interesting drawings.

But for those who want to construct a perforated fabric, it is not only the question of producing more or less perforation that preoccupies him. He is generally eager to perform these days in a way pleasing to the eyes, he tries to produce a drawing if possible, at the same time as a day. It is often the object to be pursued in armored gauzes, whether all the threads are of the same size, and that one seeks to produce a drawing by the armor itself, or that the straight threads are And that all interest is concentrated on the play of the threads of a cord, for example, or of a color very opposite to that of the rest of the fabric.

In the first case, that is to say, if all the right and tower wires concur in the production of the desired optical effect, it is by the successive groupings of wires and blows that one will seek to produce the Openwork parts that will alternate with the solid armored parts in taffeta. For example, a gauze bar with a solid part and an up-to-date part will be made by working straight yarns and threads of taffeta turns on 9 strokes, and then grouping 3 strikes together as shown in FIG. If these groups of blows are repeated several times as in the drawing of FIG. 2, a true bayadère can be obtained, a solid effect and a perforated effect.