- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

So-called Savoyard rocker

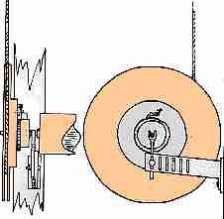

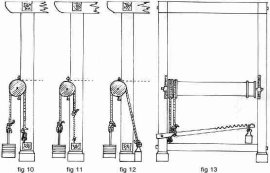

In order to avoid the continual rebounding of the counterweights to their low position, a sort of so-called Savoyard rocker has been devised in which the rope is very long while being wound around the collar of the roller before passing through a pulley fixed to the ceiling . The counterweight must then be replaced only when it has reached the ceiling after allowing 3 to 4 meters of chain to be unrolled. This kind of rocker, which is generally used as a load of the pile chain rolls in cut pile-cut velvet, has all the advantages of the rising rocker without requiring too often the re-adjustment of the counterweights.

Rollover, so-called

The so-called woven bascule consists of a rope wound two and a half turns or three and a half turns round the collar of the roller. The front end of this rope is attached to either a fixed point, a counterweight or a spring. The other end for the rear receives the necessary load to the tension of the chain.

The rope turns wound on the clamps have the purpose of enclosing them and thus forming a powerful braking which opposes the unwinding of the wires, the power of this plane being given by the more or less heavy load placed at the rear.

In general, the shoulder scales are mounted with two ropes, one for each side of the roller and the load consists of cast iron counterweights, attached, suspended or suspended on a horizontal crossbar that connects the two strings. In the Lyonnaise region, this crossbar loaded with weights is frequently replaced by a box containing heavy objects: a few stones, cast iron weights, etc.

The wallet scale is widely used for fabrics made in Lyons when the tension to be given is not too great.

This kind of rocker has the advantage of letting the chain unwind with regularity, and of being sufficiently elastic to avoid jerks. Depending on the type of fastening used for the front end of each rope, two different types of rocker can be obtained.

The dry scale (that is to say fixed)

This rocker is obtained by attaching the rope forwards in front of the roller at a fixed point, around the loom of the loom (low back cross member), or to a piton fixed to the ground. The rocker thus arranged is hardly elastic and consequently lends itself little to the movement of the threads during the work. It is used only in certain fabrics where the chain must be held very tight by the forced reduction given to the fabric.

The movable flip-flop

It is said to be movable when the end of the rope forwards in front of the roller is attached to a counterweight or a coil spring. With this type of rocker, more elasticity, more sensitivity is obtained than with the dry rocker. It must therefore be used for the weaving of delicate unified or shaped fabrics such as taffetas, faults, satins of Lyon, taffeta shapes, etc ...

Roman rocker

The lever rocker called the Roman rocker comprises, like the rocker, a rope wound 2/2 1/3 to 3 ½ turns around the roller collars. The front end of this rope may also be fixed in three ways: at a fixed point, a spring or a counterweight, but the rear end of the rope instead of receiving a series of counterweights or any load Is subjected to the action of a lever of the first or second type depending on whether it is placed below or above the roller.

The most widely used Roman scale is constructed with a lever of the second type placed underneath the roller. The fulcrum of this lever is at one of its extremities, and is constituted by a strong cord attached to a fixed point.

The resistance point is formed by the descending chord of the roll and the variable power of the lever is given by a more or less heavy counterweight placed at the other end and at a variable distance from the resistance point.

When the Roman rocker is formed by a lever of the first kind, it is placed above the roller, the fulcrum of the lever is then located inside and is obtained by means of a rope, the heel Attached either to a key of the craft or to a strong traverse bearing on the estases. The point of resistance always formed by the rope coming from the roll is at one end of the lever whose power is given by a counterweight at the other end. This lever is thus arranged with a lever of the first kind in certain special looms such as shaped velvets in which the creel in which the pile coils are placed is situated beneath the chain roll.

According to the laws of the levers, it will be understood that in the Roman lever, the longer the lever arm and the shorter the resistance arm, the greater the power on the roller and the greater the chain tension.

The different chain tension is thus obtained by moving the counterweight on the arm of the lever which is notched in sawtooth for this purpose. The tension is reduced by bringing the counterweight closer to the point of resistance while increasing it by moving it away.

The Roman rocker has the advantage over other rockers to give a very high power with a low counterweight and consequently to be inexpensive of installation (sic), it is very elastic and is used successfully in the trades of which The threads have a great movement to produce. On the other hand, it has the disadvantage of allowing the chain to unwind, so that it can not be used in very delicate fabrics which require a perfect regularity in the tension of the warp threads. As in the wagon, as the front end of this string is fixed to a fixed point or to a moving point, the rocker is said to be dry or movable. The flip-flop is used when the tension of the wires is not too strong whereas the dry flip-flop is used when the chain is very pulling and the grid is difficult to tighten.

Rocker type Roman roller

The so-called roller-type rocker is a kind of rocker-type brake that stands in the middle between the ordinary Roman rocker and the rocker. It also holds the middle as the disposition of these two kinds of rocking. The rope that forms the brake is wrapped around the roller collar 2 ½ turns or 3 turns and ½ as appropriate. In front the rope is attached either to a weight or to a spring or directly attached to the ground or to a fixed point. In the first case it takes the name of mobile flip-flop, in the second of flip-flop. At the rear of the loom, the end of the rope is hooked about half a turn to a small roller placed horizontally about 15 cm above the clear (bottom crossbar) which connects the two rear legs of the loom . This small roller is pierced through and through by a few holes which pass through its center, and which make it possible to place in various positions a bar of wood or iron of 40 to 60 cm on which the counterweight is placed. The bar of the counterweight having its free end forward does not interfere in any way since it lies below the chain roller and the length of the loom. In order to increase the power of the rocker, it is sufficient to move the counterweight away from the small roller, in order to decrease the power and consequently the tension of the chain, bringing the counterweights of the small roller closer together. As in the case of the other types of rockers, the increase or decrease in the tension of the chain may be given by the number of turns of rope wound around the collar of the chain roll and generally two ropes are provided, one for Each collar of the beam, as well as two small rollers with their bar loaded with counterweights.The so-called Roman roller-rocker gives very good results, its regularity of action is intermediate between the rocker scale and the Roman rocker and it has the advantage of following the movement of the chain very well. It also gives high power with low load.

Flip-flop to tension wires

In the majority of fabrics, the yarns which are to form the selvedges, generally referred to as cords, do not function according to the weave used for the warp yarns. It is therefore necessary when they have a different slot to place them outside the chain roller where the wires of the part are located. To do this, we use large coils of turned bouses called restaings on which all the wires of the cords are folded. The restaings, so that they can unroll the threads they command, rotate on a rod fixed by two small supports placed generally (but not necessarily) underneath the chain roller. The tension given to the cords must of course be related to the type of armor chosen, the nature of the wires and the reduction given to them. It is obtained by means of small brakes arranged generally according to one of the types of rockers used for the warp yarns. It is most often a saddle brake consisting of a rope of suitable size wrapped 1/2 turn or 2 1/2 turns of the collar of the restaing by receiving a counterweight back. A brake is also successfully used consisting of two strips of cloth or cloth which enclose the collars of the restaing and which oppose the unwinding with more or less power depending on whether the load is increased or decreased Suspended and the coil springs hanging thereon.Whatever the brake mode used for the cords, the tension of these wires must be checked constantly because nothing is more unsightly than cords less pulling or pulling than the fabric. This is a very important point because it can depreciate and decrease the market value of the fabric.In fabrics where the cords must be worn according to an armor which does not allow them to stop the weft, it is necessary to add to the cord wires 1 or 2 additional wires called cordelines. These wires, made of large materials, wound on small coils, have brakes similar to those of cords.

Riser

This name designates a certain type of warp brake in which the power is given by a more or less heavy counterweight suspended at the end of a rope wound and taken by its other end by a pin (pedonne) driven into the Collar of the roller.

As the weaving progresses, the string follows the movement of the roll and thus wraps around the collar of the roller by an amount equal to the unrolled chain length.

The riser is used in hand looms for the weaving of certain very delicate fabrics because it gives a very great equality in the tension by obeying with much regularity to all the movements of the threads of the chain.

This scale is used very rarely because it requires constant monitoring by the weaver. When, in fact, the counterweight reaches the height of the collar, it must be lowered to the ground, for it could not follow the movement of the roller. For this purpose, the end of the loop-shaped rope which is fixed to a peg is uncoupled and then hooked again when the counterweight has been lowered.

In this kind of rocker, a counterweight is usually placed on each side of the roll, and in order that the repositioning of the counterweights can not lead to bad weaving, it is necessary that they never be at the same height. The installation is then done on one side first, then after a certain amount of woven fabric, on the other side.

Scales

The apparatus used to keep the chain stretched in looms of all kinds is generally referred to as a rocker. These flip-flops whose device is very variable must also allow the rolling to be carried out regularly as the weaving proceeds. The different models used in the hand looms vary according to the type of fabric to be made. They are strictly speaking only brakes which act on the chain roller and oppose with a regularity and a power more or less great to the unwinding of the wires.

Most silk fabrics can only be produced in perfect conditions with perfectly uniform chain tension. The slightest inequality can produce a fabric of irregular appearance, characterized in the direction of the weft by bright parts alternating by matt parts.

The regularity of action of a flip-flop is therefore of the highest importance and the flip-flops, whatever their shape, must be studied in this direction.

To this it should be seen in the choice of a rocker the elasticity to which it can be lent during the running of the loom to the movement of the threads during opening and closing of the pitch and the power with which it can To oppose the unwinding of the threads. This power can be modified by the worker from time to time as the chain unwinds and in relation to the decrease in the diameter of the roll so that the tension of the chain is constant over its entire length.

Different scale models can be divided into three categories:

1 / - the risers

2 / - the scales to be worn

3 / - Roman rocker levers

Practical hand weaving course

Lyon Municipal Weaving SchoolProfessor A.CREPT - Year 1912-1913

The handwritten course has been copied by us.This hand weaving course on looms was used until the 1980s.