- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

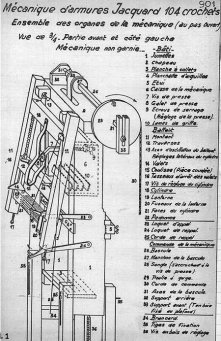

Armor mechanics Jacquard system, so-called mechanical 104

The so-called mechanical armor 104 (hooks) is used for the formation of the plain or armored fabrics obtained by means of healds (frames). Its purpose is to cause the movement of the healds according to an order indicated by the armor, that is to say by the movement which it is necessary to carry out with the warp threads so that they can produce the fabric crossed with the cuttings.

Almost all of these mechanics have been constructed to be able to actuate the healds at the rising, that is to say by an upward movement given at each blow to the healds whose wires must pass over the weft, these healds returning to their first position

At the closing of the step while the other healds remain stationary at the position at which they were placed at the time of organization of the loom.

Some mechanics have been constructed so that the heddles can be actuated with each stroke by raising and lowering, that is to say both by a given ascending movement to the healds whose wires must be above the weft and a movement of descent given to the healds whose wires must lie below the weft.

The raised or lowered healds meet at the closing of the pitch by the movement opposite to that given at the time of passage of the shuttle.

Built

The frame of the mechanism is made of wood, it is composed of two uprights called binoculars connected to their base by a board pierced by 104 holes on which the hooks rest and called board with collars. At their upper part the binoculars are united by a strong wooden tray, called the hat. Around the middle of the height, against the binoculars is fixed a small plank also pierced with 104 holes whose aim is to support the needles on the side of their point, this board is called planchette of needles. At the same height and on the other side the hands rest on a grid formed of small iron pins taken in the binocular and sufficiently spaced to receive the heels of the needles.

Garnish

The mechanical seal consists of 104 needles and 104 hooks.The needles are made of round wire wound on itself to form two rings. The first, elongated, is located at one end of the needle and takes the name of heel, it is in this ring that passed the pin (large thin point) which keeps the needle in place in the To prevent it from escaping from the gate and falling. The second, which is round or elongated (depending on the shape of the hook), is situated at a variable distance from the heel, the end of the needle opposite the heel takes the name of the tip. The needles are placed inside the machine on 4 horizontal rows and are supported on one side by the needle board, on the other side by a grid.

The hooks are also made of round wire, but somewhat larger than that of the needles, they are bent on themselves at the lower point, which is called the heel, and at their upper part they are curved in the form of Beak to be able to hook onto the claw blades and to be raised when the needles engage them, the upper part of the hook is referred to as the head.

The hooks are arranged vertically and each rest above a hole in the snail board. The collar is a long rope ring straddling the heel of the hook and ends at the bottom with a carabiner, connecting the hooks to the ropes supporting the heddles.

Case

The box is called a box containing 104 small springs called elastic, which is placed behind and against the heel of the needles. The purpose of the elastics is always to push the needles, and hence the hooks, into the position necessary for their operation.

Mechanical body

The body of the mechanism is located between the binoculars, it carries the blades of the claw or knives loaded to lift the hooks engaged by the needles. This body receives an upward and downward movement given by the rocker, it is traversed by the pressing screw which carries at one of its ends a roller, the other end is a piton fixed to the body using A strong wing nut and a lock nut for adjusting the press screw.

Mechanical Toggle

The rocker is the organ that controls the body of the mechanism in a movement of rise and fall.At the beginning of the mechanics, the lever was composed of a lever whose fulcrum was located on the cap, the small arm of this lever was connected to the body by an iron rod, the other arm of the lever Extending in front of the craft and receiving the rope of the step which the workman maneuvered.This device has long since been abandoned and the lever is replaced by a shaft supported on one side by a bushing fixed on the cap of the mechanism and on the other side by a support in the form of a T fixed to the ceiling. On this shaft is placed a wooden sleeve after which is secured a strap carrying a hook taken at the press screw, at the other end of the shaft is a large grooved pulley which receives the chord corresponding to the step .

Flywheel

The leaf of the 104 is composed of a movable frame supported by adjustable screws forming pivots and taken in two supports fixed to the cap of the mechanism. In front of the wing is fixed a piece of forged flat iron, curved in a desired shape and designated under the name of bent piece. The wing carries the cylinder, a piece of wood in the shape of a quadrangular prism, each face is pierced with 104 holes and carries two small conical ankles made of hardwood used for the training of cartons, these ankles are called pedonnes.The cylinder is held stationary when it presents cartons against the needles by two valets, pieces of T-shaped wood at their base pressing against the cylinder, and pressed by a strong spring.On the right side of the cylinder is an iron cage called lantern, used for the cylinder drive. The cylinder is driven by a latch in the form of a hook which is secured against the front binocular and rests on the lantern. Below the lantern is a second latch, called the return latch, which is used to rotate the cylinder backwards.

Practical hand weaving course

Lyon Municipal Weaving SchoolProfessor A.CREPT - Year 1912-1913

The handwritten course has been copied by us.This hand weaving course on looms was used until the 1980s.