- Home

- Resurrection ▾

-

Learn ▾

- Free library

- Glossary

- Documents

- Initiation

-

Shaped fabrics

- Introduction

- Popularization

- Definitions

- Le métier de façonné

- Principes du façonné

- Mécaniques de façonné

- Le jeu des crochets

- Les cartons

- Chaîne des cartons

- Mécanique 104 en détail

- Pour en finir

- Montage façonné

- Empoutage 1/3

- Empoutage 2/3

- Empoutage 3/3

- Punching, hanging and dip

- Autres façonnés

- Façonnés et Islam

-

Cours de tissage 1912

- Bâti d'un métier

- Le rouleau arrière

- Les bascules

- Formation du pas

- Position de organes

- Mécanique 104 Jacquard

- Fonctionnement 104

- Lisage des cartons

- Le battant du métier

- Le régulateur

- Réduction et régulateur

- Mise au métier d'une chaîne

- Mise en route du métier

- Navettes à soie

- Battage

- Ourdissage mécanique

- Préparation chaînes et trames

- Equipment ▾

- Chronicles ▾

- Fabrics ▾

- Techniques ▾

- Culture ▾

- Language ▾

Front roller blocking system seen from the ratchet and the toothed wheel attached to the side of the roller

Front roller blocking system

Hoist system for the frames (aerial view)

Shuttle launch system

Front beam

Back beam

Shuttle boxes

Other details photos:

1

Beam shaft AR: Length = interior width of the loom minus 2 cm

A: section 65 mm x 65 mm

B: diameter 60 mm, L 6 cm

C: section 30 x 30 mm, L 6 cm

2

3

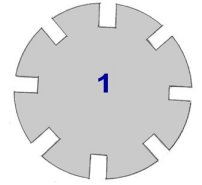

Diameter 33 cm drilled in the center of a round hole of 60 mm

19mm (thickness) plywood

1

8

Length = inside width of the loom minus 2 cm

5 cm x 2 cm

Qty

Length

Sleepers

Section

Part Num.

The rear roller has 2 flanges (1) 33 cm in diameter drilled in their center with a 65 mm square hole for the passage of the wooden shaft. The flanges have 8 notches 2 cm wide by 5 cm high which will receive the 8 cross members.

2

Length = 15 cm

Diameter 12 mm

Threaded rod + 2 nuts

3

Diameter 15 cm drilled in the center of a round hole of 12 mm

19mm (thickness) plywood

1

8

Length = inside width of the loom minus 2 cm

4 cm x 2 cm

Qty

Length

Sleepers

Section

Part Num.

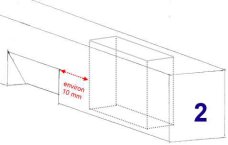

The front roller has 3 flanges (1) 15 cm in diameter drilled in their center with a 12 mm round hole for the passage of a 12 mm threaded rod. The flanges have 8 notches 2 cm wide by 4 cm high which will receive 8 cross members. The flanges are threaded onto the threaded rod and locked with nuts: one flange at each end, the third in the center. The 8 crossbars are then fixed.

Front and back rollers

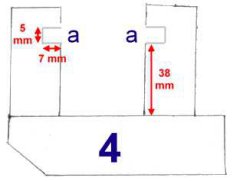

The four boards of the shuttle boxes are grooved along their entire length, at a. The groove is 7mm deep by 5mm high. They should allow the rats to slide with a certain amount of play.

Through this recess passes the upright 1 of the leaf. Its exact dimensions must correspond to the section of the uprights 1 of the leaf, to allow them to just slide in. Part 3 has the same recesses.

Detail of parts 2, 3 and 4

NB: In the "Section" column, the first number is the width and the second number is the thickness.

1

4

1

1

2

Qty

3,5 cm x 12 cm

6 cm x 2,8 cm

225 cm

40 cm

152 cm

152 cm

95 cm

5

4

6 cm x 5 cm

3

6 cm x 5 cm

2

6 cm x 5 cm

1

Section

Part Num.

The pedals are drilled for the passage of a threaded rod (diam. 12 mm). Two brackets are used to hold them. A washer is inserted between each pedal to limit their contact. The other end of the pedals will receive eyebolts to connect them to the steps.

These sleepers can be assembled alongside the frame by tenons and mortises or half-timbered assembly reinforced by brackets, depending on your skills and the tools you have. Crossbars B and E act as rear and front chest pieces.

We have chosen 47.24" of weaving, choose your width ...

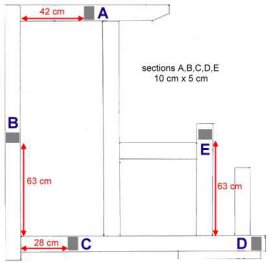

Plan of the loom : the sides

Total length : 74.80"

Total height : 63.38"

Loom frame + shuttles boxes = width of frame loom + 19.68" + 19.68"

Width of the loom frame = weave width + 3.94"

Dimensions

It is one of our weaving looms, Scandinavian type but realized in France in the years 1980-1985. Inspired by the Swedish Glymakra trades, widely distributed in Europe, this business brings them important improvements, in particular concerning the beams back and front.

This loom also has the advantage of being simple to manufacture. It does not include any molded parts that are not easily constructed by a handyman who is somewhat equipped to work with wood.In addition, 90% of its components use a single section of wood, which will facilitate supply.

We will therefore provide you with everything you need to manufacture yourself or have this craft manufactured by a carpenter:

- The complete detailed list of all the parts composing it.

- A complete, detailed and entirely side plan.

- Detailed photos.

- Simple, comprehensive descriptions, advice and explanations.

Simple construction, you can choose yourself the desired width.

Main Features :

- Made of oak, you can use a less expensive wood, such as beech, or even pine (provided it is very dry and dense).

- Assemblies by tenons and mortises.

- Suspended flap.

- Shuttle and shuttle boxes.

- Warping-warping machine with a diameter of more than one meter.

- Braking of the back beam by ropes and counterweights (wallet).

- Advance of the front roller by lever (ratchet wheel).

- Built-in bench.

- Four (or more) frames, six (or more)

- Independent control of the frames, lifting system, pulley control.

You will thus have a loom, solid, safe and well designed which will bring you the greatest satisfaction for a very reasonable budget.

If you are a beginner, you will be able to consult the other sections of the site, existing or future to know how to complete your material and to learn how to weave.

Build your loom

In vain having looked for on Internet the free plans of a correct loom,

we decided to realize them and to supply them to you ourselves...

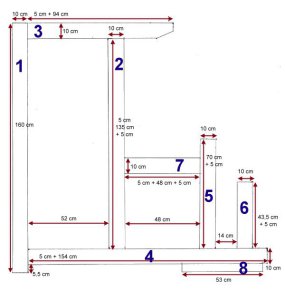

Part Total length Section Qty

1 160 cm 10 cm x 5 cm 2

2 145 cm 10 cm x 5 cm 2

3 99 cm 10 cm x 5 cm 2

4 159 cm 10 cm x 5 cm 2

5 75 cm 10 cm x 5 cm 2

6 48,5 cm 10 cm x 5 cm 2

7 58 cm 10 cm x 5 cm 2

8 53 cm 5,5 cm x 5 cm 2

Part Longueur totale Section Qty

A, B, C, D, E 120 cm 10 cm x 5 cm 1